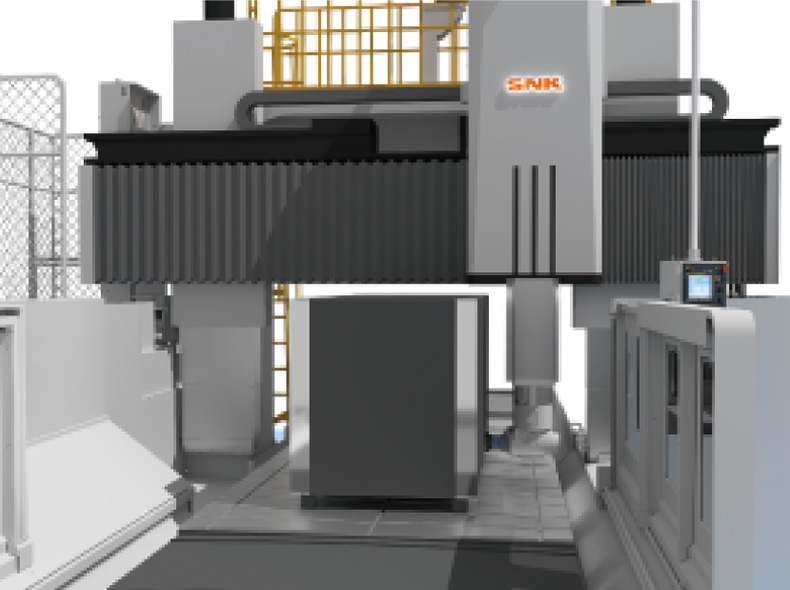

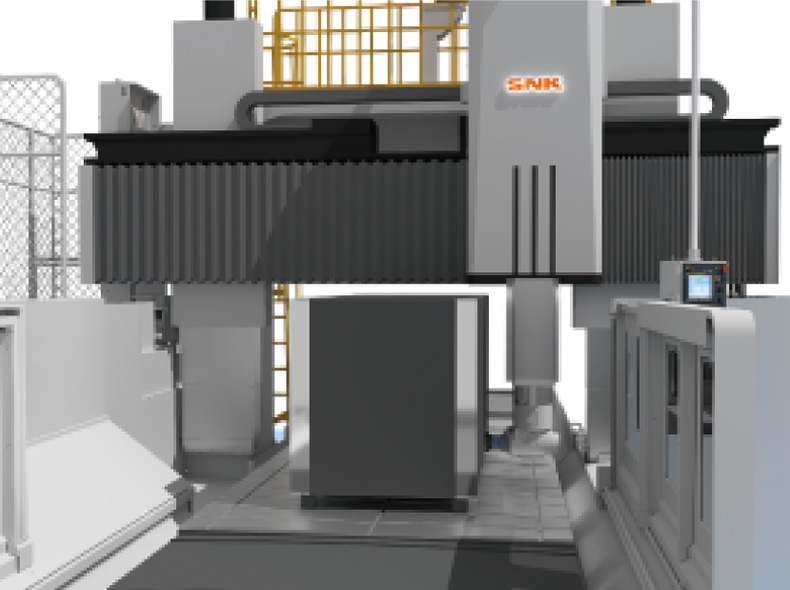

NeoVDouble column type 5-face machining center

- Automotive

- Aerospace

- General machining

- Shipbuilding

- Heavy electric

- Material

- Semiconductor

- Specialized machines

A 44kW high-speed, high-torque machining center that pursues and focuses on productivity.

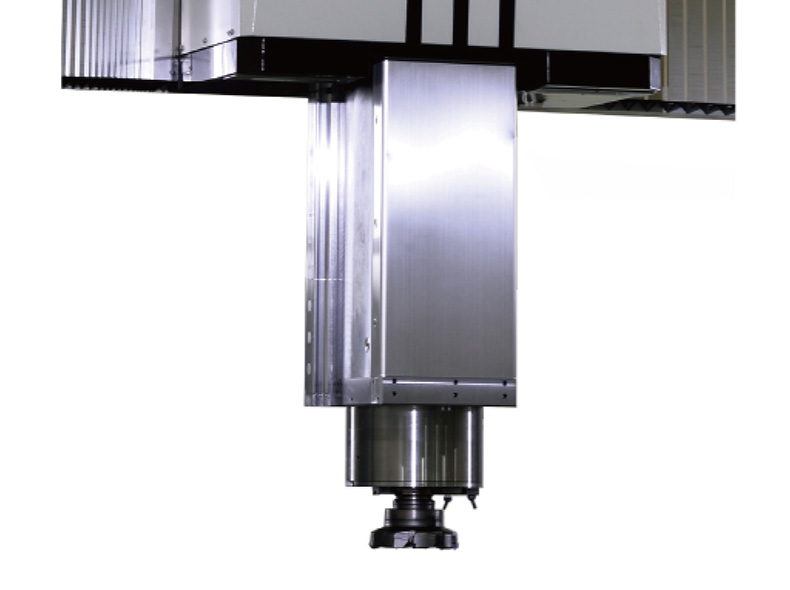

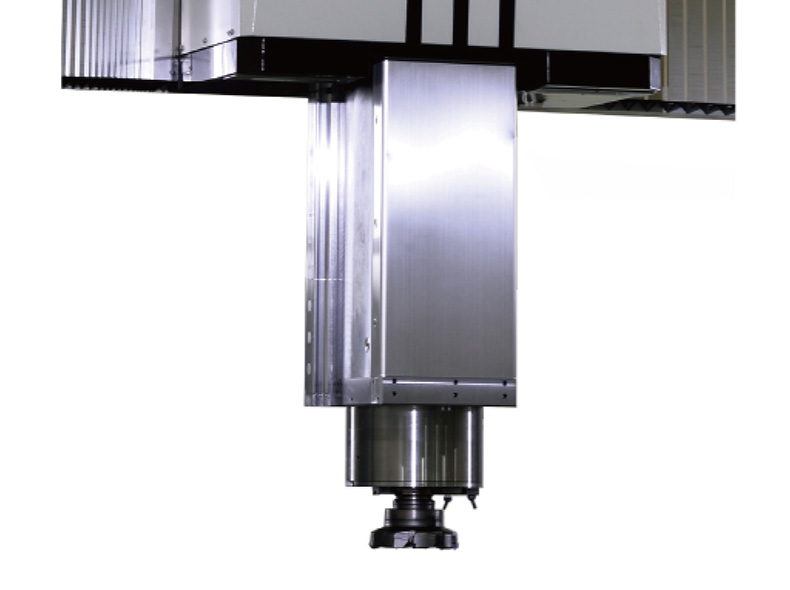

The structure of Neo-V while being highly-rigid, it also achieves high precision stability, bringing it to a next level of productivity. Strong materials have been used for the large-type ram and large-circumference curvic ring, allowing not only powerful machining throughout all the Z-axis stroke, but also, thanks to the strong clamping of attachments, powerful side machining as well.

Main specifications

Features

1Equipped with a powerful 44kw spindle in both vertical and horizontal spindles.

Powered by the 350x350mm square ram and built-in twin motor, the 44kW・1,200N・m high-power spindle allows Neo-V to stand at the peak of its class when it comes to chip emission. This feat is also demonstrated even when the angular attachment is equipped for side machining.

2Highly-rigid structure that supports high-speed and high-HP machining.

SNK could not be more proud of the precission stability achieved by holding the spindle head with a large-type ram, which at the same time is supported by a wide crossrail and wide columns. In addition, by using double screw DCG (driven at the center of gravity) in both Z and W-axis, high stability through heavy-duty machining is also possible.

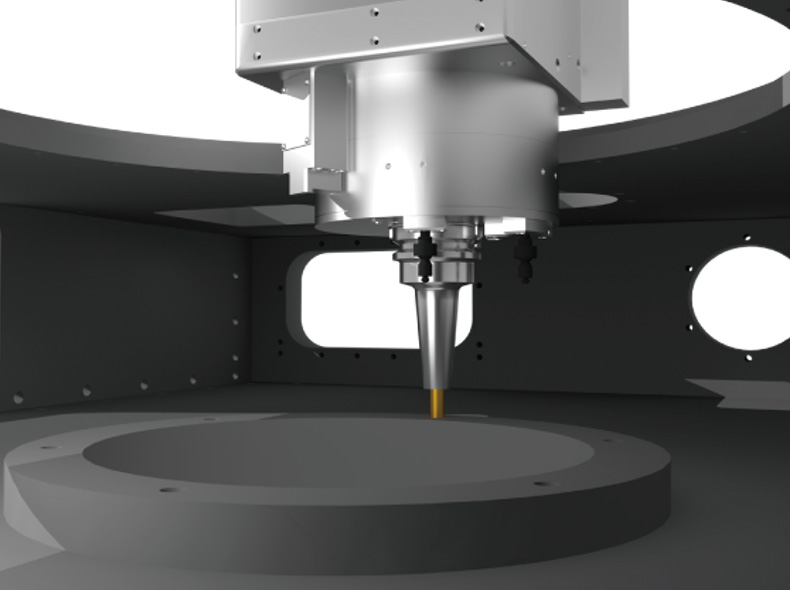

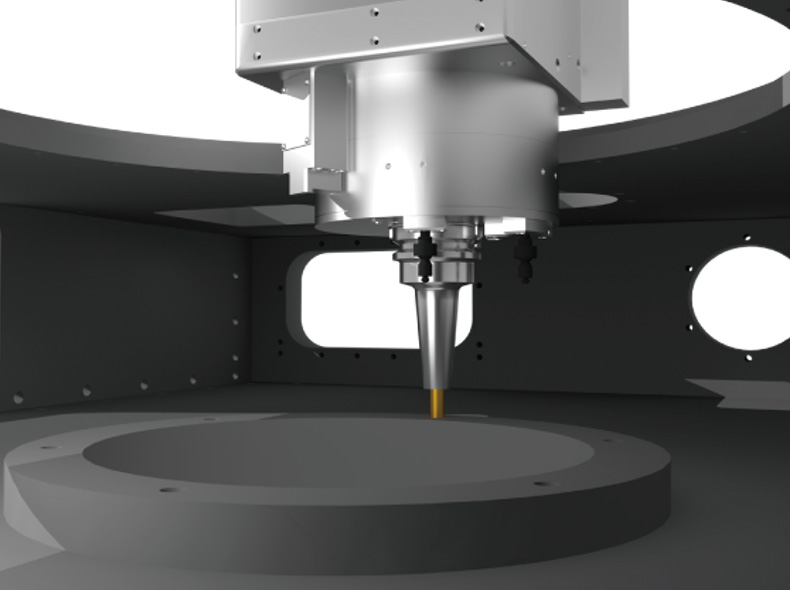

3High-speed extension attachment suitable for die machining.

From roughing to finishing, the 12,000min-1 extension attachment allows machining of dies made of hard materials. Incorporating it with our high-precision and high-speed control software, DCS, excellent surface quality die production can be achieved.

Movie

Related products

(Double column type 5-face machining center)

DCⅡ

Electricity consumption reduced by approx. 30%! Masterpiece die & mold processing machine pioneering the carbon-neutral era

- Effective distance between columns (mm)

- 2,000~3,500

- Table working surface (mm)

- 3,000×1,500~6,000×3,000

- Spindle speed range (min-1)

- 40~6,000 (Maximun 20,000※)

※ With attachment

HF

A super-large machining center with outstanding cutting power.

- Effective distance between columns (mm)

- 2,000~4,000

- Table working surface (mm)

- 4,000×1,500~7,000×3,500

- Spindle speed range (min-1)

- 30~3,000