Machine Tools

With 120 years of expierence with the core of manufacturing, machining centers, SNK as a large type machining center manufacturer, holds a high sense of duty offering machining centers around the world that can create never seen before products. Throughout our history through accumulated unparalelled know-how by trial and error, SNK has learned to make faster, stronger and preciser machines that challenge global standards. While implementing new technologies, SNK will continue to offer the best machines for our customers.

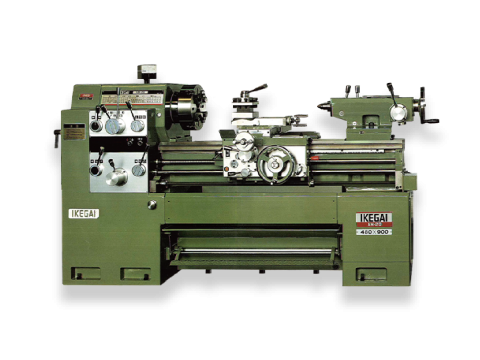

As a group we offer both [NISSIN MASHINE CO.,LTD.] and [IKEGAI CORPORATION.] products.

-

Double Column Type Machining Center

Double Column Type Machining Center

-

5-Axis Machining Center

5-Axis Machining Center

-

Lathe・Composite Lathe

Lathe・Composite Lathe

-

Special Purpose Machine

Special Purpose Machine

-

Honing Center・U-Center

Honing Center・U-Center

-

Horizontal Boring Machine

Horizontal Boring Machine

-

Grinding machine

Grinding machine

-

FMS Automation system

FMS Automation system

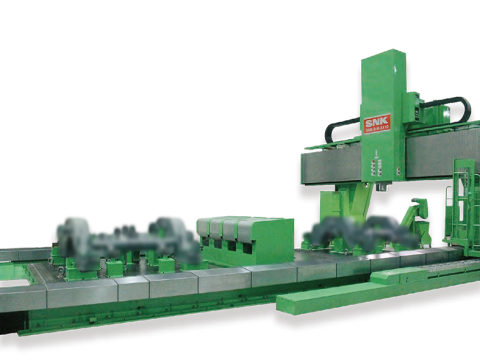

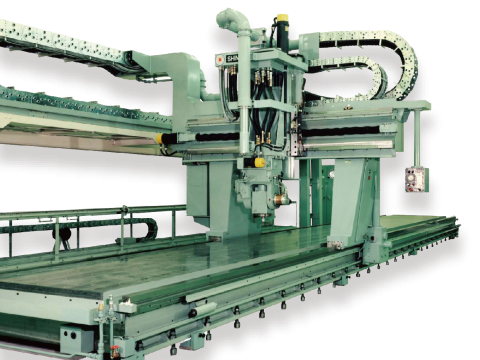

Double Column Type Machining Center

SNK is a pioneer in double column type machining centers. Thanks to out rich lineup of sizes and a wide variety of spindle capabilities, we are able to offer the best fitting machine centers for our various customer’s demands.

Table type

NeoV-MⅡ

Double column type 5-face machining center with a structure that combines high rigidity and stable precision to support high productivity

- Effective distance between columns (mm)

- 2,100~4,600

- Table working surface (mm)

- 3,000×1,500~8,000×4,000

- Spindle speed range (min-1)

- 30~5,000

RB-MⅢ

Continuously evolving High-performance Double Column Type 5-face Machining Center

- Effective distance between columns (mm)

- 2,100~3,600

- Table working surface (mm)

- 3,000×1,500~6,000×3,000

- Spindle speed range (min-1)

- 40~6,000

(Maximum 10,000)

RB-FⅡ

A highly rigid continuous 5-axis machining center than can perform powerful 5-axis machining.

- Effective distance between columns (mm)

- 2,100~4,100

- Table working surface (mm)

- 3,000×1,500~6,000~3,500

- Spindle speed range (min-1)

- 40~6,000

(Maximun 30,000)

(Double column type 5-face machining center)

DCⅡ

Electricity consumption reduced by approx. 30%! Masterpiece die & mold processing machine pioneering the carbon-neutral era

- Effective distance between columns (mm)

- 2,000~3,500

- Table working surface (mm)

- 3,000×1,500~6,000×3,000

- Spindle speed range (min-1)

- 40~6,000 (Maximun 20,000※)

※ With attachment

HF-MⅡ

Outstanding power and unlimited customizability

- Effective distance between columns (mm)

- 2,700~4,700

- Table working surface (mm)

- 4,000×2,000~8,000×4,000

- Spindle speed range (min-1)

- 10~4,000

Gantry type

GMB

A gantry type 5-face machining center designed to easily cut through iron.

- Effective distance between columns (mm)

- 5000

- Spindle speed range (min-1)

- 30~4,500

PS/PM/PSR

A space efficient, highly productive five axis machining center.

- Spindle speed range (min-1)

- 20~19,800

HGM

High rail gantry type machining center designed for fast aluminum workpiece machining.

- Effective distance between columns (mm)

- 4,400~5,400

- Spindle speed range (min-1)

- 500~20,000

MKS

Designed for fast 5-axis machining of large design models.

- Effective distance between columns (mm)

- 3,900~4,900

- Spindle speed range (min-1)

- 100~15,000

HLM

The best option for machining composite materials.

- Effective distance between columns (mm)

- 3,000~5,000

- Spindle speed range (min-1)

- 100~15,000

5-Axis Machining Center

SNK has thoroughly engaged in developing 5-axis machining centers. Starting with our double column type machining center, our vertical and horizontal machining centers create new value expanding the boundaries of machining.

Table type

RB-FⅡ

A highly rigid continuous 5-axis machining center than can perform powerful 5-axis machining.

- Effective distance between columns (mm)

- 2,100~4,100

- Table working surface (mm)

- 3,000×1,500~6,000~3,500

- Spindle speed range (min-1)

- 40~6,000

(Maximun 30,000)

CMV

A tilting spindle head and a rotary table eliminate the effects of heavy workpieces, allowing for high precision 5-axis machining.

- Pallet working surface (mm)

- 1,000×1,000~1,500×1,500

- Spindle speed range (min-1)

- 40~8,000

GHP

Aimed for aluminum machining, this machine is global leader in productivity.

- Pallet working surface (mm)

- 4,000~6,000×2,000

- Spindle speed range (min-1)

- 150~30,000

HPS-A/B

Horizontal profiler with imposing chip emission capabilities.

- Pallet working surface (mm)

- 3,048×1,220~6,000×1,500

- Spindle speed range (min-1)

- 150~20,000

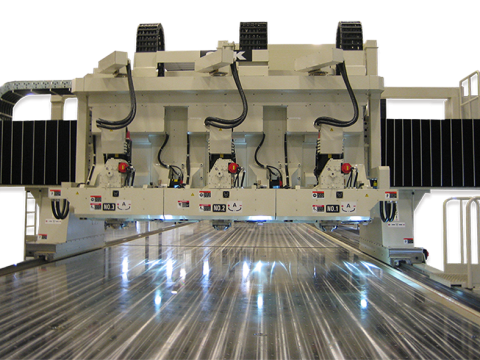

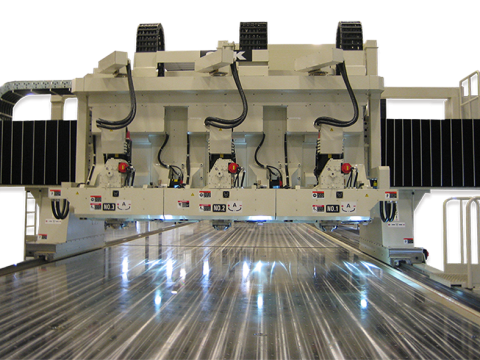

Gantry type

PS/PM/PSR

A space efficient, highly productive five axis machining center.

- Spindle speed range (min-1)

- 20~19,800

HGM

High rail gantry type machining center designed for fast aluminum workpiece machining.

- Effective distance between columns (mm)

- 4,400~5,400

- Spindle speed range (min-1)

- 500~20,000

MKS

Designed for fast 5-axis machining of large design models.

- Effective distance between columns (mm)

- 3,900~4,900

- Spindle speed range (min-1)

- 100~15,000

HLM

The best option for machining composite materials.

- Effective distance between columns (mm)

- 3,000~5,000

- Spindle speed range (min-1)

- 100~15,000

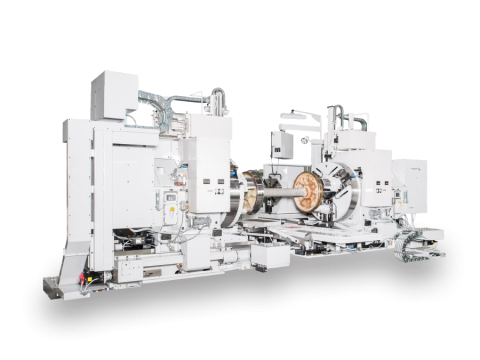

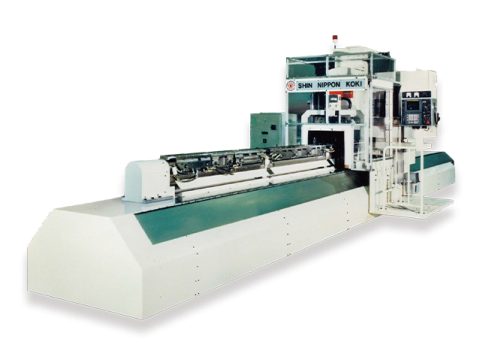

Lathe・Composite Lathe

SNK also offers lathes from long-established Ikegai. We are backed up with achievements withing several industries such as seacraft and iron manufacturing that use large type lathes.

Conventional lathe

NC lathe

SR

4-guideway lathe for roll machining with very high machine rigidity

- Max turning diameter (mm)

- 500 ~ 2,000

- Distance between centers (mm)

- 4,000 ~ 10,000

- Max load capacity (Kg)

- 8,000 ~ 85,000

EXL

High-efficient machining of workpieces that require multiple processes with a lathe spindle with a high-horsepower motor and a 5-axis milling spindle

- Max turning diameter (mm)

- 470 / 800

- Distance between centers (mm)

- 540 / 2,450 / 5,150

- Turning spindle speed (min-1)

- 100 ~ 10,000 / 50 ~ 5,000

VT

Single column CNC vertical lathe capable of face milling, boring and outer diameter turning

- Max turning diameter (mm)

- φ1,350

- Max load capacity (Kg)

- 4,000

SVT

Large vertical lathe series with powerful cutting ability for high productivity of large parts

- Max turning diameter (mm)

- 4,000 ~ 7,000

- Distance from table top to spindle end (mm)

- 2,150 ~ 2,900

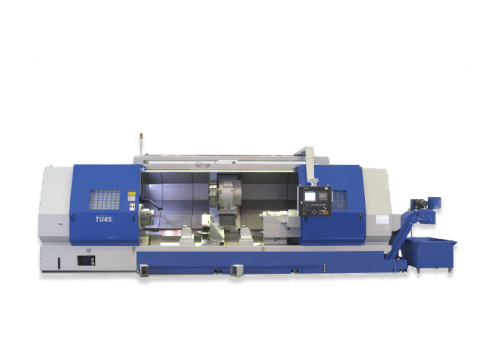

TU

Great capability for heavy-duty cutting of large-diameter center workpieces and chuck workpieces

- Max swing (mm)

- φ500 ~ φ850

- Max turning diameter (mm)

- φ350 ~ φ650

TC

CNC lathe designed to process as large a workpiece as possible

- Max swing (mm)

- φ500

- Max turning diameter (mm)

- φ370

AU(ANC)

Horizontal two-guideway CNC lathe with great accessibility to the workpiece center.

- Center distance (mm)

- 1,000~

- Main axis rotation speed(min-1)

- 1.6~500

TNC

Large three-guideway CNC lathe with compact footprint.

- Center distance (mm)

- 1,000~

- Main axis rotation speed(min-1)

- 1.6~400

RNC/TNC-S

Horizontal four-guideway CNC lathe with separated / integrated saddle and work bed

- Center distance (mm)

- 6,000~

SBK / SBT Super lathe

Exceptionally rigid and high-performance roll lathe

- Center distance (mm)

- 6,000~

- Main axis rotation speed (min-1)

- 1.2~215

NST/NK

A lathe designed to machine crankshafts and camshafts for the automotive industry.

- Center distance (mm)

- 570~

- Main axis rotation speed (min-1)

- 1.4~1,500

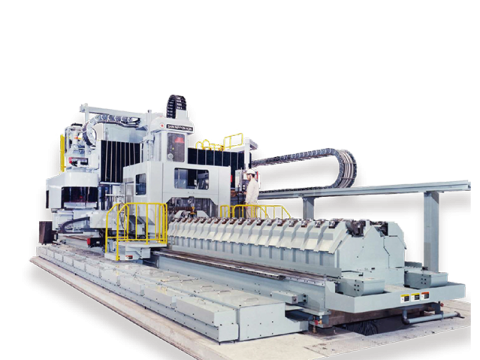

Special Purpose Machine

By using our know-how on large type machining centers, we offer new and specialized machines that accommodate the needs of our customers. We are backed up by achievements in the aerospace and construction machinery industries.

Special machine for aerospace

5-axis honeycomb mill

5-axis machine for machining honeycomb materials for aircraft

- Table size (mm)

- 11,000 x 1,500

- Distance from table top to spindle end (mm)

- 610

- Spindle speed (min-1)

- 2,000 ~ 20,000

5-axis drilling machine

High-efficient machine that automates drilling of aircraft wings. Enabled accurate drilling of curved surfaces by automatically measuring wing inclination and misalignment.

- Crossrail longitudinal travel (mm)

- 15,000

- Ram vertical travel (mm)

- 1,600

- Spindle speed (min-1)

- 3,000 ~ 12,000

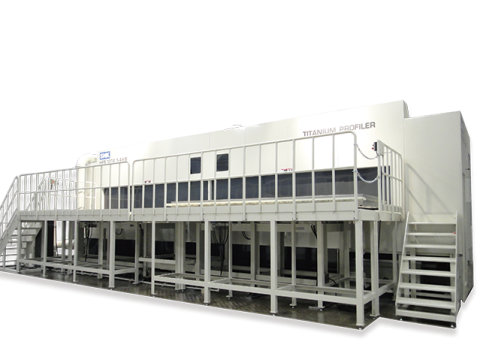

5-axis skin mill

Special machine for high-efficient and precise machining of outer panels of aircraft fuselages

- Table size (mm)

- 12,000 x 2,600

- Distance from table top to spindle end

- 750

- Spindle speed (min-1)

- 30 ~ 10,000

Stringer mill

Special machine for aircraft stringer (wing reinforcement)

- Table size (mm)

- 7,000 x 700

- Spindle head vertical travel (mm)

- 300

- Spindle speed (min-1)

- 5,000 ~ 20,000

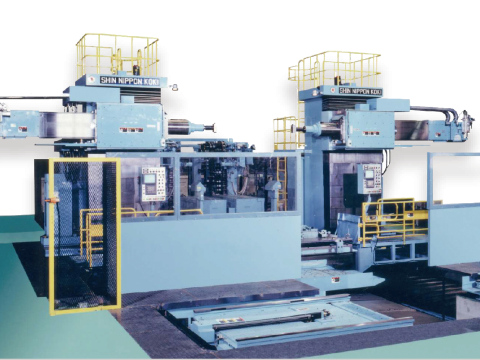

Special machine for general machine

KRS

Simultaneous double-sided machining of construction machinery parts is enable by 2-head-facing spindles

- Spindle head saddle vertical travel (mm)

- 2,300

- Spindle head transverse travel (mm)

- 1,000

- Spindle speed (min-1)

- 60 ~ 6,000

TMS

Open-side type machine suitable for machining large workpieces

- Column longitudinal travel (mm)

- 6,000

- Spindle head transverse travel (mm)

- 2,500 ~ 4,000

- Spindle speed (min-1)

- 30 ~ 3,000

Special machine for semiconductor

Silicon ingot cylindrical grinding machine

Automatically grinding the outer surface of silicon ingots

- Spindle power (kW)

- 5.5

- Work size (mm)

- Max Φ320 x 2,000

Silicon ingot bandsaw

Automatic silicon ingot cutting

- Spindle power (kW)

- 2.0

- Work size (mm)

- Max Φ320 x 2,800

Silicon wafer polishing machine

Mirror finishing machine for silicon wafers

- Spindle power (kW)

- 0.4

- Work size (mm)

- Φ300

Special machine for rail industry

Special machine for material

KN

Special machine capable of processing all types of knots or patterns

- Max turning diameter (mm)

- φ500

- Max distance between centers (mm)

- 2,000 / 2,500

- Max load between centers (Kg)

- 3,000

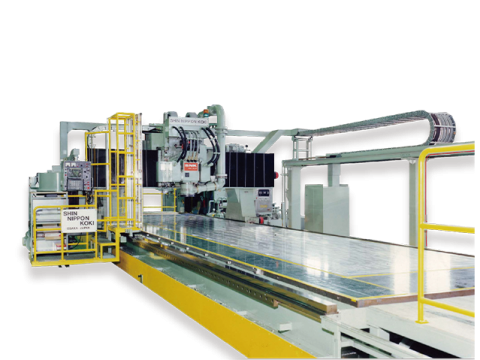

MS

High-precision, high-efficiency and fully automatic aluminum ingot face milling machine

- Max ingot thickness (mm)

- 640

- Max ingot width (mm)

- 2,130

- Max ingot length (mm)

- 9,150

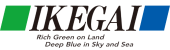

Special machine for shipbuilding

SLX

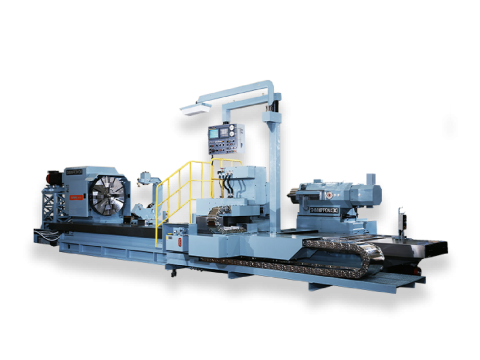

Large combined lathe that combines attachment-changing horizontal machining center and lathe

- Max turning diameter (mm)

- 1,500

- Distance between centers (mm)

- 6,500

- Milling spindle speed (min-1)

- 60 ~ 4,000

CJL

Lathe specialized for medium and finishing turning of crankshaft journals

- Swing over bed (mm)

- φ3,000

Honing Center・U-Center

A multi tasking honing machining center made up of a combination of high-efficiency boring machining and high-precision honing finishnig.

Machining centers, either vertical or horizontal, equipped with U-axis mechanism are U-centers.

Honing center

U center

Horizontal Boring Machine

A horizontal boring machine equipped with U-axis mechanism.

Horizontal boring machine

BNC

U-axis control equipped CNC horizontal boring machine that can apply the built-in face plate

- Table size (mm)

- 950 x 1,050 / 1,400 x 1,600

- Spindle speed (min-1)

- 10 ~ 1,600

NB

Table type for small and medium-sized workpieces and planer type for large workpieces are available, CNC horizontal boring and milling machine with excellent operability

- Table size (mm)

- 950 x 1,050 ~ 1,600 x 1,800

- Table load capacity (Kg)

- 2,500 ~ 10,000

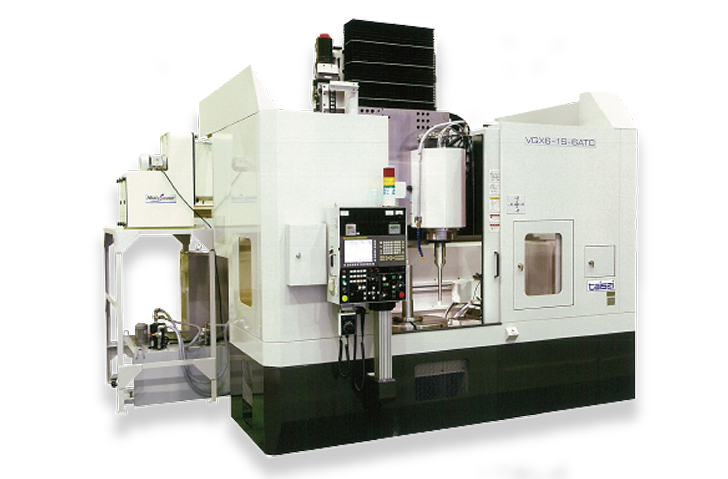

Grinding machine

Designed by TAISEI KIKAI, this grinder is capable of machining inner and outer diamaters as well as the edges of cylindrical workpieces, decelarator parts and other special workpieces.

Grinding machine

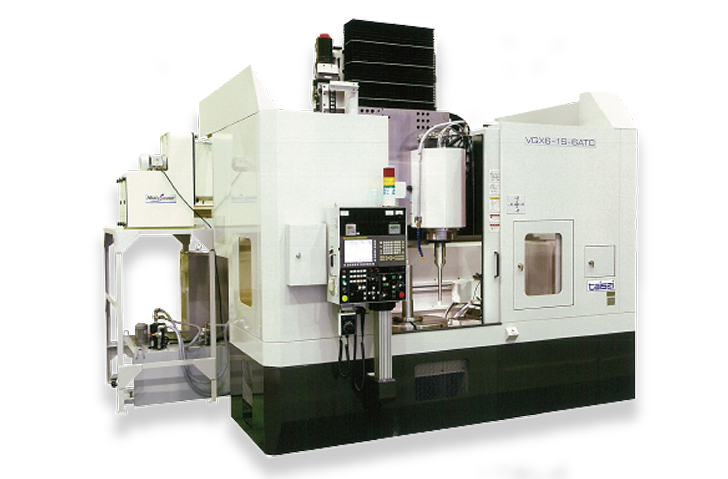

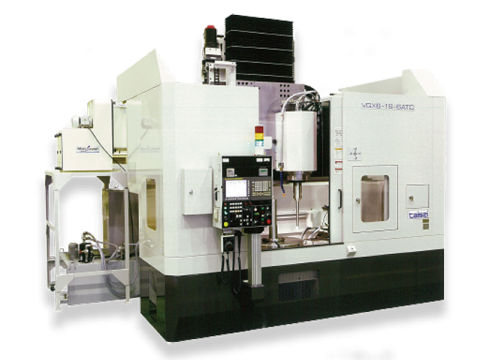

VGX

Aiming to achieve the high-accuracy, high-rigidity and high-productivity. Customizable grinding machine

- Max inner diameter (mm)

- φ400 ~ φ1,200

- Max outer diameter (mm)

- φ600 ~ φ1,400

- Max length (mm)

- 550

VRG

Vertical in /out grinding machine for deep holes and large diameters enabled by unique spindle technology

- Max inner diameter (mm)

- φ50 ~ φ600

- Max outer diameter (mm)

- φ700

- Max depth (mm)

- 450

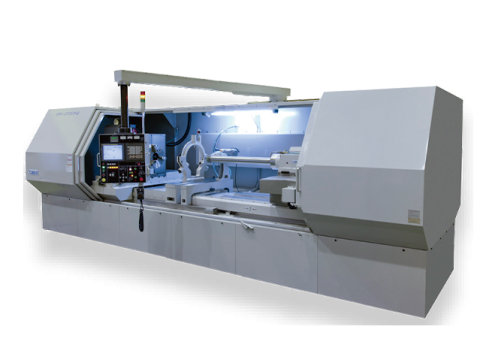

GRI

Highly accurate and practical horizontal internal grinding machine developed from the user's standpoint

- Max inner diameter (mm)

- φ50 ~ φ500

- Max length (mm)

- 1,000

FMS Automation system

Flexible response to product and information changes with a production system that supports high-mix and small-lot production. Automated transfer and management of parts and products enables mixed production of similar products or multiple products within a certain range without having to drastically change production equipment. Contributes to productivity improvement by labor saving in workpiece transfer and setup in large machine operation.