Engineering service

SNK offers engineering support for our customers before and after acquiring our machines. In order for our customers to use our products in the most effective way, SNK starts off offering not only the best machine for each workpiece, but also solutions and support for machining/maneuvering problems and worries.

Before acquiring SNK’s machining center

Machining study

SNK will propose the optimal machine to machine the analyzed workpiece of our customer.

Time study

A machining simulation on the proposed machine. SNK will propose the best machining process for our customers, showing the positive impact of SNK’s products.

Machining test

In order to offer a visual representation of the capabilities of our products, SNK offers to actually do machining tests for our customers.

After acquiring SNK’s machining center

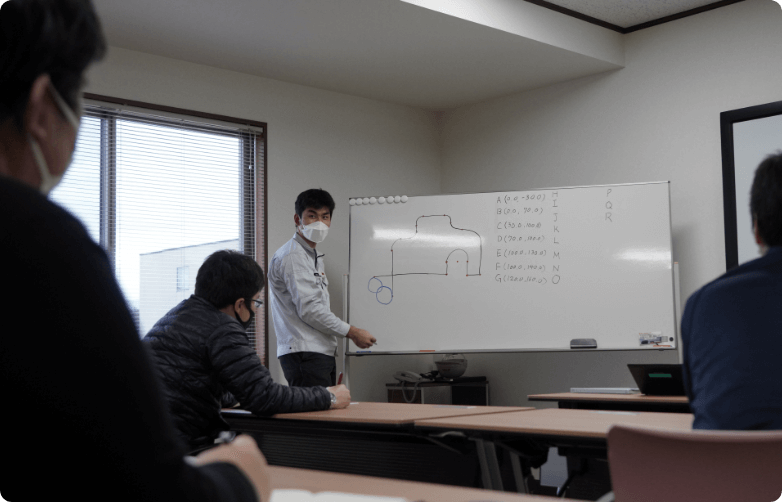

NC training

SNK offers to train new operators unfamiliar with NC program and machining centers. SNK offers two courses, basic and advance, where operators can learn through lectures and practical training, different skills and know-how on how to operate and use our machining centers.

▶ Basic course

A course aimed for operators with no knowledge on NC operation. This course focuses on creating a strong foundation in NC operation.

▶ Advanced course

This course focuses on SNK’s original 5 face machining software. This course is aimed for operators with NC operation knowledge.

Please contact our sales department or customer-EG for training application or inquiries.

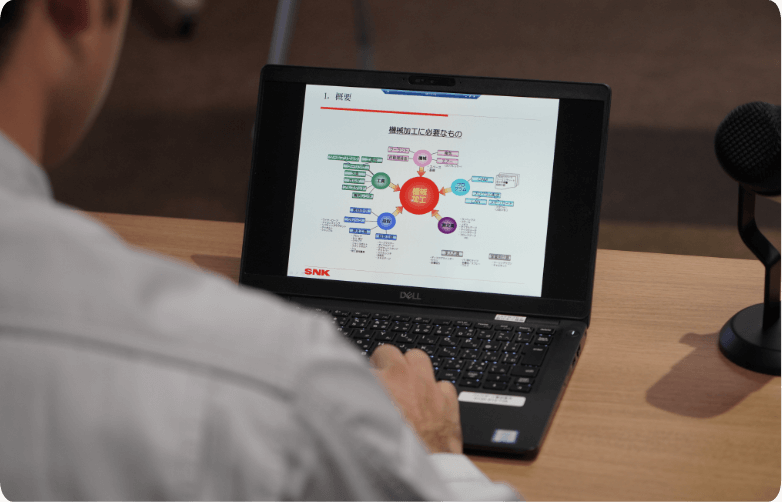

Online training

“I do not really know this part”, “I get it, but I just can’t get a full grasp of it”, for this and more small questions and doubts SNK offers free online training.

* We set the time limit to 1 hour for each online training.

*Please contact our sales department or customer-EG for inquiry and booking. Please let us know your worries and concerns before hand.

Operation guidance and machining practice

SNK offers in the spot operation guidance for the machine acquired. If requested, SNK’s staff will also machine a workpiece in the spot. As the guidance is offered in the spot, smooth communication between both parties is secured, resulting in better results.

*A separate contract will be issued if machine practice is requested.

Machining analysis・Chatter test

If our product does not cut properly or the surface quality is not good, SNK offers to use our own analysis software and work with alongside our customers to solve the problem.

Technology exchange meeting

From identifying operation status to offer machining methods for our customers, SNK offers to work and support customers in the form of technological exchange meetings to find improvement points.

Education program

This education program is aimed for new employees or operators with no experience using machining centers. SNK offers to train and guide employees in our own factory. For more details please reach our sales department.

Machining inquiry examples

We have an environment that allows us to perform a variety of tests, from general processing to die machining,

5-axis machining, and more. We will propose new solutions while facing the challenges of our customers.

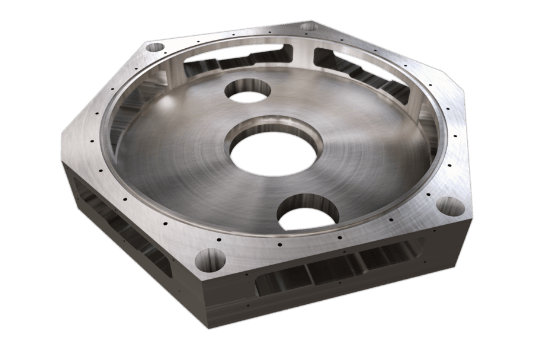

CASE. 1

Q. We use a vertical machine but chips accumulate and it takes time to clean. We would like to make the workpiece standing and cut horizontal for easier cleaning. But we do not have a horizontal machine and do not know how to set the workpiece for horizontal cutting. Also, we do not have enough time to stop production for test cutting.

A. SNK will set the workpiece standing and cut it with Double column machine. Please see the chip accumulation. First, please consider whether it is possible to perform the process with the existing machine, then we suggest considering the horizontal machine.

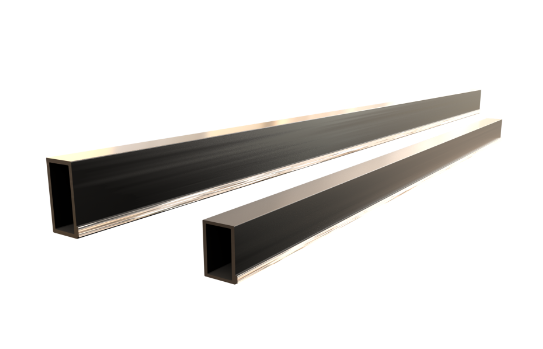

CASE. 2

Q. We perform surface and hole machining on 4 surfaces of square pipes and change the workpiece setting on the manufacturing process. We use a holding jig but workpiece rigidity is low and is susceptible to distortion, making it difficult to keep accuracy. Is there a better way to use the holding jig as little as possible and set the workpiece only once?

A. A holding jig is unnecessary when using a magnet jig. It is possible to process the underside face with an angular attachment and angular head. This makes it possible to process 4 surfaces without changing the workpiece setting.

CASE. 3

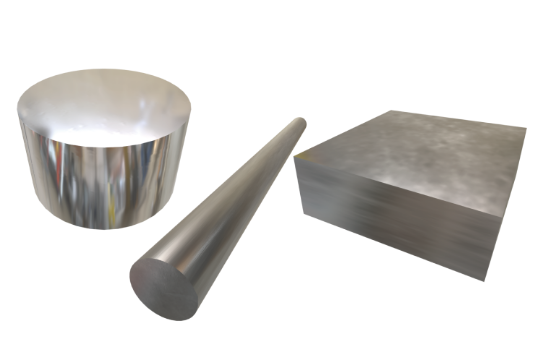

Q. We will start working with materials that we have never used before. We are not sure that we can cut it with our existing machine. Can you give advice?

A. SNK has knowledge on a multitude of materials, such as iron, aluminum, titanium, plaster, brick resin, etc. We provide consultation on any material.