Corporate Information

Message from Managing Director

“Connecting with CustomersCreate with customers”This is our mission of manufacturing.

President and Representative Director

Akira NAKANISHI

SNK can continue to improve “MONOZUKURI”

for 30 years together with our customers

The large-type machining centers manufactured at SNK are made to last for more than thirty years in the workplace of our customers all around the world. It is not rare to see overhauled machines that last for nearly fifty years as well. It is our mission, as a large type-machining center manufacturer, to continue being responsible of machines that have been delivered after even thirty or fifty years.

The large numbers of inventions that our machining centers have been able to produce for our customers, helping to make society a better place, is SNK’s motivation, driving us to keep contributing on the creation of new value in the automotive, aerospace, industrial, semi-conductors and even more industries. Our customers range from large well known multinationals to SMEs run by a small group of people. Even after delivery of our machining centers, SNK continues to visit the workplace of our customers regularly, in search of places where we can help improve the product of our customers. I myself visit our customers’ workplace around the world to maintain communication with them in regard to their aims and tasks of their products, as well as to understand their vision of the future that would come from those products.

There is no correct answer in manufacturing. Every company has their own strength and each of them keep on improving every day. SNK looks at every company individually, understanding their positions and their strengths, we keep developing technology, machines, and solutions that will benefit all of our customers.

As a leading company in the large-type machining center industry, we keep on strengthening ourselves to keep up pace with a world that changes very often. Regardless of all the experience we have accumulated from the past, SNK’s engineers and technicians keep on thorough training regularly, acquiring new knowledge every day. I believe that this is necessary to evolve the products around the world and only then we can contribute in creating an even better society.

Supporting society with unique materials

Besides machining centers, SNK is also in the centrifugal cast pipe industry. SNK has been manufacturing elaborate and high quality cast pipes since 1962. Such cast pipes are produced by pouring molten cast iron or cast steel into a rotating cylindrical mold, rotating it to cover the inside with the iron or steel utilizing centrifugal force, then solidifying. SNK’s centrifugal casted pipes are silent supporters of society. Our pipes are used as supporting columns in stations; as seismic isolation devices in skyscrapers; as a spool to roll aluminum; as a large hydraulic cylinder; as a machine component for food production and many other places where they are not easy to spot. There is an infinite number of characteristics when it comes to centrifugal cast pipes. Parameters vary from the combination of materials, the melting temperature and time, the temperature at which it is casted as well as the rotation speed of the mold, between many others to choose from. SNK is able to select and follow the best recipe for each usage, controlling molten steel at a temperature exceeding 1500℃.This monozukuri requires high skill and technique proficiency. SNK keeps on training its engineers and technicians regardless of all the years of experience, in order to meet the specific characteristics of the pipes that its customers need for different industries such as construction, steel, and industrial machinery. The number of companies that are able to produce big size centrifugal cast pipes is very low, and unfortunately that number is going down. However, we are confident that there are characteristics that only these pipes can achieve, and I know that these are important pieces that support our society as well.

( About “Monozukuri”)

The direct translation of monozukuri to English is manufacture or the production of a good. While this translation is correct, it loses most of its cultural meaning when doing so. Consisting of two words, ものthings, and づくり、production, ものづくり, also refers to the art, tradition and hard work of making something, as well as it also expresses skill, dexterity and perfection. Monozukuri is a key element to Japanese manufacturing and it best expresses our stance towards production. We, SNK, have our own tradition and expertise, and we are open into implementing new knowledge and know-how in order to improve our own monozukuri, and help improve our customers’ monozukuri.

While holding this sense of duty, each SNK worker keeps on developing new skills and focuses their efforts on being a company that shapes new monozukuri alongside its customers.

Corporate Profile

| Name | SHIN NIPPON KOKI CO.,LTD. | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Incorporated | September, 1949 (Founded:1898) | ||||||||||||||||||||

| Executive |

|

||||||||||||||||||||

| Main Business Activities | Machine Tools (Various Machining Centers(Double Column Type ・ Vertical Type ・ Horizontal Type)、Large Lathes、Composite Machines, and Special Purpose Machines)・Industrial Machines・Softwares・Centrifugally Cast Steel Pipes Production and Sales of the above |

||||||||||||||||||||

| Capital | 100 million yen | ||||||||||||||||||||

| Employees | (Non-consolidated) 706 (January, 2025) (consolidated) 985 (January, 2025) |

||||||||||||||||||||

| Head Office Address | 〒590-0157 2-500-1,Takao,Minami-ku,Sakai,Osaka Click here for access | ||||||||||||||||||||

| Main TEL. / FAX. | TEL. +81-72-271-1201 / FAX. +81-72-273-5594 | ||||||||||||||||||||

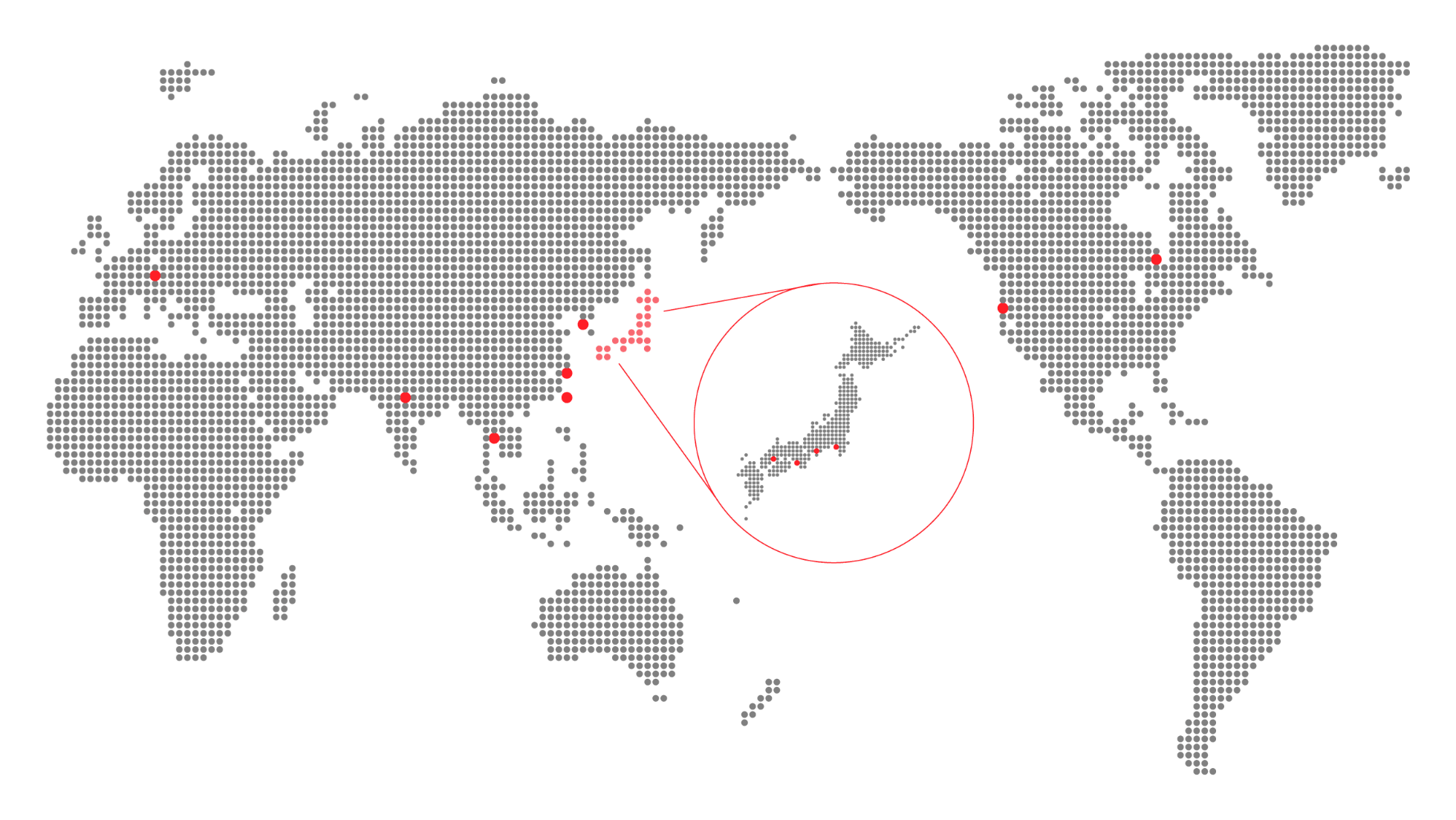

| Affiliates |

|

History

| 1898(M31) | Takisaburo Wakayama opened “Wakayama Iron Works”, which was the predecessor of SNK. Produced manual punching machine of stepping type and manual 6 feet lathe. |

|---|---|

| 1904(M37) | Wakayama Iron Works devoted to the production of machine tools. |

| 1920(T9) | Reorganize “Wakayama Iron Works Co.,Ltd.” |

| 1943(S18) | Shidayama factory was started to operation. |

| 1949(S24) | Company name was changed to “Shin Nippon Koki Co., Ltd.” and it was established. |

| 1956(S31) | SNK was affiliated with Daiwa Can Company group. |

| 1958(S33) | Misaki factory was completed, starting its operation. The first RB-II precision vertical boring and milling machine, the prototype of the double column type processing machine, was completed. |

| 1959(S34) | Development of large double column type machine began in earnest. |

| 1962(S37) | Started production for centrifugally cast steel pipes. RB-III NC precision vertical boring and milling machine, the first NC large double column type machine in Japan, is completed. |

| 1965(S40) | The completion of the PK-80 copying die carving machine was a stepping stone to the automotive and die industries. |

| 1967(S42) | “Nissin Machine Co.,Ltd.” which deals with a small lathe was affiliated with SNK group. The completion of the SM milling machine for wing spar was a stepping stone to the aircraft industries. |

| 1968(S43) | “SM-13” NC milling machine for wing spar won The 3rd Japan Society for the Promotion of Machine Industry Prize sponsored by JSPMI. (Awarded jointly with Kawasaki Aircraft Co., Ltd.and Fujitsu Limited.) |

| 1969(S44) | The completion of the NC drilling machine TM-25V was a stepping stone to the shipbuilding industries. “MM-1520” laser non-contact type model measuring machine won The 11st One of the Best 10 Products in Japan Awards sponsored by The Nikkan Kogyo Shimbun. (Awarded jointly with Mitsubishi Electric Corporation) |

| 1970(S45) | FM-720 Multics Machining Center, the first simultaneous 5-axis control machine tool in Japan, is completed. |

| 1974(S49) | Shinodayama Plant’s Technical Center was completed. |

| 1980(S55) | “SNK AMERICA,INC.” was establushed in Chicago, USA. |

| 1982(S57) | Shinodayama factory’s Precise Technical Center was completed. |

| 1983(S58) | Established the concept of high-speed, high-precision die machining with the development of die machining control technology DCS-Ⅰ. |

| 1987(S62) | Pursued elimination of manual finishing on machining centers with development of the DC-4 high-speed profile milling machine. |

| 1990(H2) | Introduced CAMOSⅡ-MP FMS for machining medium-sized machine parts in Shinodayama Factory. |

| 1992(H4) | “DC series” High-Speed Profile Milling Machine won The 2nd Japan Society for Die and Mould Technology Prize Sponsored by JSDMT. |

| 1996(H8) | Developed new 5-face machining software for automated coordinate transformation. “SNK Nanjing Corporation.” was established in Nanjing, China. |

| 1997(H9) | Shinodayama factory was converted into a constant temperature/humidity-controlled factory. |

| 1998(H10) | SNK have obtained the Quality Mangement System ISO9001. “SNK ENGINEERING KOREA Co.,Ltd.” was established in Seoul, Korea. |

| 2001(H13) | “SNK ENGINEERING TAIWAN Co.,Ltd.” was established in Hsin-Tien Dist. New Taipei, Taiwan. |

| 2002(H14) | SNK have obtained the Environmental Mangement System ISO14001. |

| 2005(H17) | Developed 5-axis high-speed high-quality machining control software “DCS-V Aero Edition” for high-speed special machines for aircraft. “RB-II Type” Precise Vertical Boring Milling Machine won the best technical prize of The 7th Honor Machine Tools of Historical Value Sponsored by The Society to Honor Machine Tools of Historical Value. |

| 2007(H19) | “SNK INDIA Private Ltd.” was established in Gurgaon, India. |

| 2009(H21) | Developed software intelligent PC that pioneered IoT technology. “PARTE-8M” Mid-Drive Multi Centers won the invention merit prize of 34th Inventor Awards Sponsored by JSAI and The Nikkan Kogyo Shimbun. |

| 2010(H22) | Developed Vertical Lathe・Vertical Turning Center “SVT series”. |

| 2011(H23) | “MS-24” Aluminum Slab Facing machine won the review board special prize of The 41th Grading Process for The Machine Design Awards Sponsored by The Nikkan Kogyo Shimbun. |

| 2012(H24) | “BFR-3500” Horizontal Multi Centers won the “Monozukuri” prize of the 55th One of the Best 10 Products in Japan Awards Sponsored by The Nikkan Kogyo Shimbun. |

| 2013(H25) | “SNK THAI CO.,LTD.” was established in Bangkok, Thailand. Set up solar power generation installation diagnostic system in Shinodayama factory. “HGM-3500” High-Speed Gantry Machine won the review board special prize of The 41st Grading Process for The Machine Design Awards Sponsored by The Nikkan Kogyo Shimbun. |

| 2016(H28) | SNK became a member of the Ikegai Group. “GHP-200B” Horizontal 5-axis Profiler won the 59th One of the Best 10 Products in Japan” Awards Sponsored by The Nikkan Kogyo Shimbun. |

| 2017(H29) | “SNK GmbH” was established in Goppingen, Germany. |

| 2018(H30) | Developed High-speed Profile Milling Machine “DC-L series”. Developed Double Column Type 5-axis Machining Center “NeoV series”. Changed the company structure from “SNK Nanjing Corporation.” to “SNK (SHANGHAI) MACHINERY CORPORATION” and “SNK NANJING TECHNOLOGY CORPORATION”. |

| 2019(R1) | “NeoV-5M” Double Column Type 5-face Machining Center won the review board special prize of The 48th Grading Process for The Machine Design Awards Sponsored by The Nikkan Kogyo Shimbun. |

| 2021(R3) | “DC-5SL” High-speed Profile Milling Machine won the review board special prize of The 49th Grading Process for The Machine Design Awards Sponsored by The Nikkan Kogyo Shimbun. “RB-FⅡ series” Double Column Type 5-axis Machining Center won the “Monozukuri” prize of the 64th One of the Best 10 Products in Japan Awards Sponsored by The Nikkan Kogyo Shimbun. |

| 2022(R4) | RB-FⅡ series” Double Column Type 5-axis Machining Center won the review board special prize of The 52nd Grading Process for The Machine Design Awards IDEA Sponsored by The Nikkan Kogyo Shimbun. SNK India Established Service Center. |

| 2024(R6) | Developed Double Column Type 5-face Machining Center “HF-MII series”. Developed Gantry Type Leser Cladding Mahince “GLC series”. |

2025(R7) | Developed Double Column Type 5-face Machining Center “NeoV-MII series”. High-speed Profile Milling Machine “DC-II series” won the review board special prize of The 55th Grading Process for The Machine Design Awards IDEA Sponsored by The Nikkan Kogyo Shimbun. |