Digital solutions

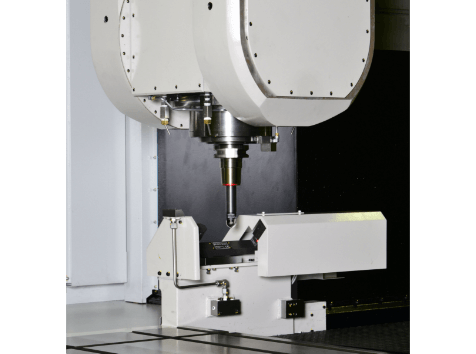

It is not possible to increase manufacturing production depending only on technological advancements of machining centers. Instead, SNK believes it is only possible by reaching the full potential of a machine by the people controlling and maneuvering the machine in an efficient way. For this reason, SNK offers software that does not only help increase production, but also that helps increase operator’s skills.

Operation management/maintenance solutions

SNK picked up comments and worries from users of large type machining centers. SNK offers a wide software lineup that focuses on improvement and progress of the workplace environment.

Machine operation management and monitoring

MT-LINKi / Si-Multi LINK

MT-LINKi / Si-Multi LINK allows users to manage and monitor operations of every machine in a facility through a device. Using MT-link along with SNK’s original data collection software, Intelligent PC, users can thoroughly analyze the status and data of their facility.

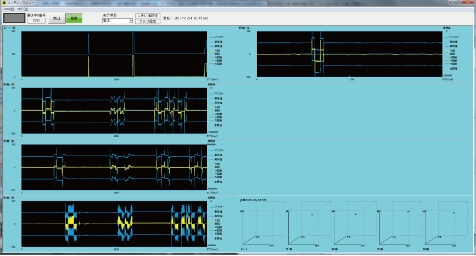

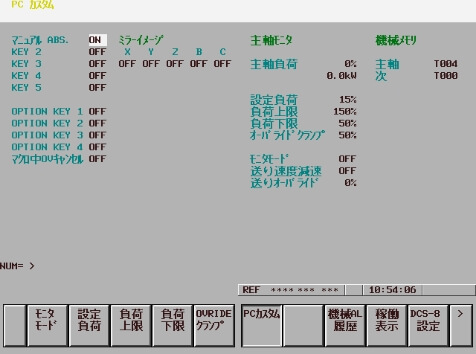

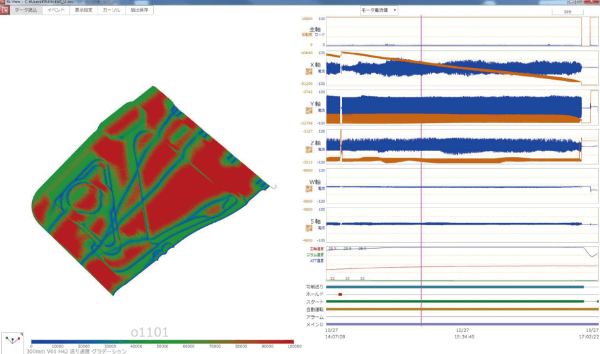

Intelligent PC

This software registers and stores more than 40 different kinds of information from the machine as digital data. Using the data obtained from Intelligent PC along with other SNK’s applications, indicators for indicator analysis can be easily spotted, leading to workplace improvement.

Preventive and predictive management

Si-PM

Based on SNK’s lifespan counter and data collected from the machine’s spindle, drive, rotation axes, and attachment, this program will send a notice for inspection to prevent any problems that could affect operation of the machine.

Remote maintenance

Si-Remote

*Only available in Japan. This software remotely connects SNK’s service center and our customers’ machines, allowing for better communication and more efficient problem solving.

Self-diagnosis function

Si-Check

This self-diagnosis program uses the machine’s axes master data and actual data from the machine to make an empirical analysis. As a result, objective conclusions can be drawn in regard of the machine’s deterioration or aging status.

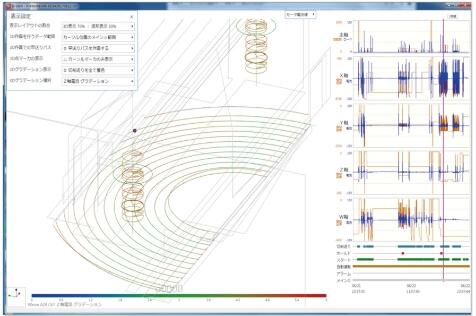

Drawing analysis

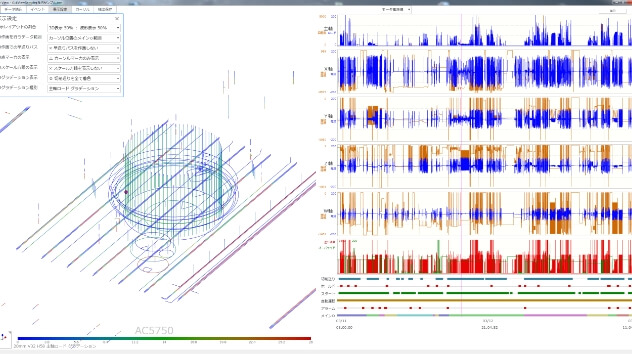

Si-View

Using data collected by SNK’ original software, Intelligent PC, Si-view creates a visual representation of the machining condition based on the tool path and specified data values. The visual representation allows visual comparative analysis.

On-site solutions

Designed to be intuitive and easy to use this lineup is aimed for NC programmers and machining center operators.

Programming support

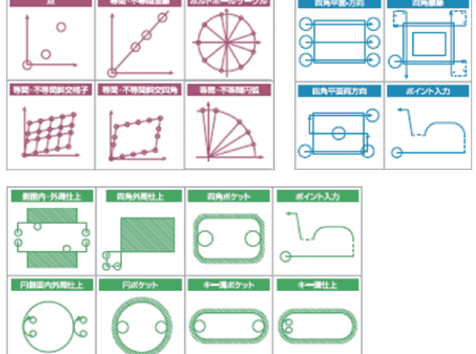

New 5-face machining software

This program controls both the Z and W axes, creating a program that considers stroke shortage and collision areas. This program brings out the best performance out of SNK’s machining centers as it makes it possible to machine high and irregular workpieces.

Interactive machining pattern software

This software allows users to make the most suitable program by only inputting the necessary values in the interactive menu in the machine, saving up programming time. This software also allows to edit the NC program that comes out of the interactive software.

Simple inclined surface machining function

The most difficult and annoying part of machining an inclined surface is setting the origin. This function deduces the inclination degree for machining in only 3 easy steps.

Functions for high precision

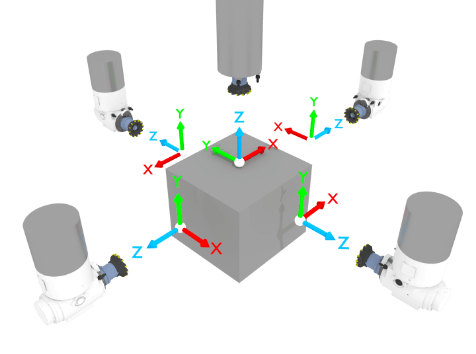

Attachment package software

When utilizing attachments, attachment data can be registered in advance for easy programming without worrying about tool positions due to tool changes, etc. or changes in conditions such as sloped surface machining. In addition, the amount of deviation between the drawing value and the actual value can be measured automatically, realizing highly accurate machining.

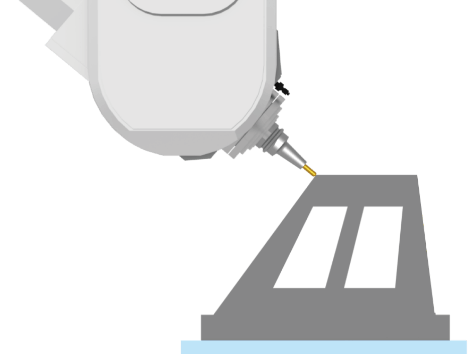

Spindle thermal displacement compensation function

This function compensates the thermal displacement in the Z-axis (spindle-direction) as a consequence of spindle rotation. It then becomes possible to machine precisely machine for a long period of with high spindle speed.

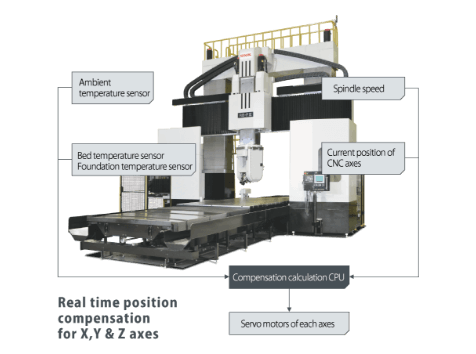

Environmental thermal displacement compensation function (TDC)

This function estimates and automatically compensates each axis’ thermal displacement in relation to the temperature of the environment, bed, foundation, etc. This function works in real time, minimizing the thermal displacement’s effect even in environments with heavy temperature changes.

Functions for automation and unmanned operation

Attachment data automatic compensation function

By registering the attachment position misalignment between the theoretical position and the actual measured position, high-precision positioning is possible. It is also possible for customers to do the measurements by their own when needed.

Automatic measurement and centering function

After machining, this function utilizes a measurement probe to do different measurements. By obtaining the coordinates of a point or measuring the diameter of a circle, this function can do different operations, such as calculating the distance between two elements or calculating the angle of two planes, etc. This function can also be used for centering operations before machining using calculation of a plane of three points, etc.

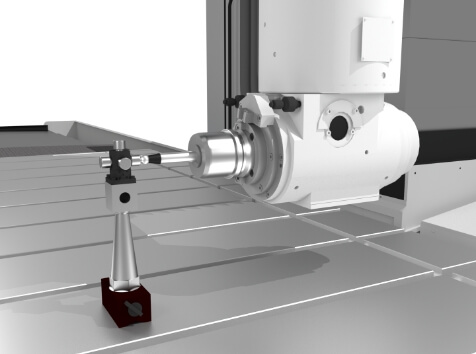

Automatic tool length/diameter measurement and tool breakage detection

Before and after machining, this function measures the length, diameter, deterioration and wear as well as deducing if the tool is broken or not. The data then automatically compensates for tool length or diameter, leading to high-precision machining. SNK offers laser-type and touch-type measurement functions.

Abnormality detection function

Si-Escape

Designed for mass production machining, this function regularly monitors the data from the machine while machining and if it finds any error between this data and the master data, it sends an abnormality notification then the machine proceeds to retract the tool and stop any operations.

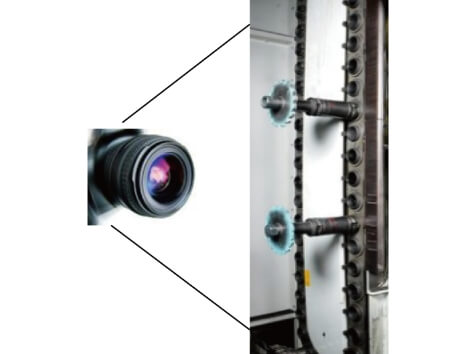

Si-ToolCheck

A camera inside the ATC automatically measures tools when they are inserted in the magazine. If the estimated measurements done by the camera and the NC program data are not congruent, this function sets off an alarm. This function is designed to prevent tooling mistakes or other human caused errors.

Cutting load constant control function (Adaptive control)

This function automatically decreases the feed rate if the spindle motor load exceeds the limit programmed in advance. This function aims to protect the machine, the tool and the workpiece from any severe damage.

FMS solutions

SNK offers a system that will let customers machine and produce several different products in the same production line.

FMS achievements

SNK’s facility counts with two FMS production lines for our machining center’s production.

・CAMOS-MP : Four 5-machining centers DC-3ASM

・CAMOS-SP : Two 5-axis machining centers, CMV-80 and two horizontal type machining centers.

Solutions aimed for 5-axis machining

5-axis machining demands complex and precise machining. In order to make it easier, SNK offers support through our user-friendly software.

Control

DCS-Aero Edition

SNK’s original high-speed die/mold control software adapted for 5-axis machining. It allows 5-axis machining for aviation industry workpieces.

Functions for high precision

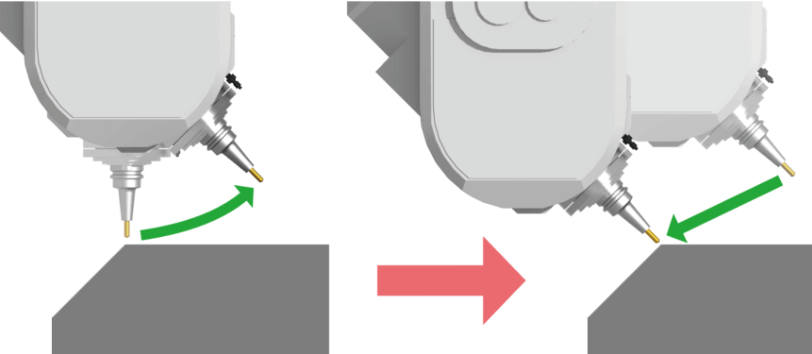

5-axis tool center point control with kinetic compensate positioning function (TCP-KCP)

This function automatically compensates in real time the tool tip position error that occurs when using TCP, tool center point control. It improves the precision of every axes, directly improving the precision of continuous 5-axis machining.

Die machining solutions

SNK offers software that consistently machines dies rapidly, precisely and with outstanding quality.

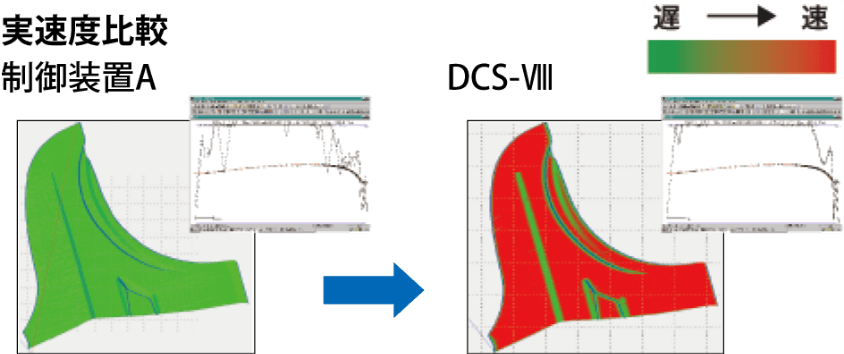

Control

DCS(Dynamic control system)

SNK’s independently developed high-speed, high-precision surface control software. Designed to keep speed changes to the minimum while increasing the number of control points in order to smoothly interpolate in a surface, DCS increases the surface quality while also decreasing the machining time. Following the design program strictly, this software stands at the top of its class.

Functions for high precision

Tool position measurement and compensation function

This function measures the mounted tool right before starting machining and compensates any misalignment it may have. By combining the tool length/diameter compensation and attachment data compensation, high-precision position can be achieved.

Thermal displacement compensation in X, Y and Z-axis due to spindle’s generation of heat

This function compensates the thermal displacement in the X and Y-axis, in addition to the Z-axis (spindle direction, as a consequence of spindle rotation. This allows to achieve high-precision, high-quality machining.

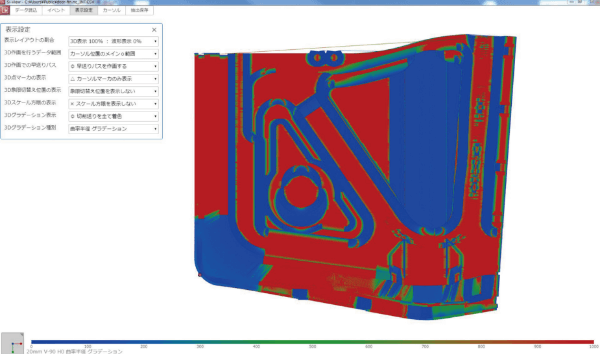

Analysis software for die machined surfaces

Si-MoldPG

This conversion program creates visual representation of the die based on its NC program. This allows for program inspections or to see the results of changing different settings in CAM. This program aims to prevent unnecessary reworks.

Si-View

Based on the data extracted from the Intelligent PC software, this program makes a visual representation of the tool path as well as set data values. This allows a visual reference for analysis when creating a program and when the machining is complete. This program can help conclude what is the cause when there’s a trouble with the surface quality of a workpiece.

Die machining support software

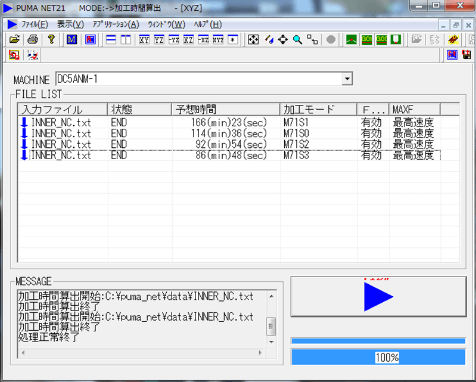

PUMA NET

The lengthy program of die machining is hard to follow. Besides of calculating the machining time, this software uses the external data transfer capabilities, DNC, to create a machining schedule that eliminates time between programs. This allows for easy way to visualize the machining process as well as increasing production.