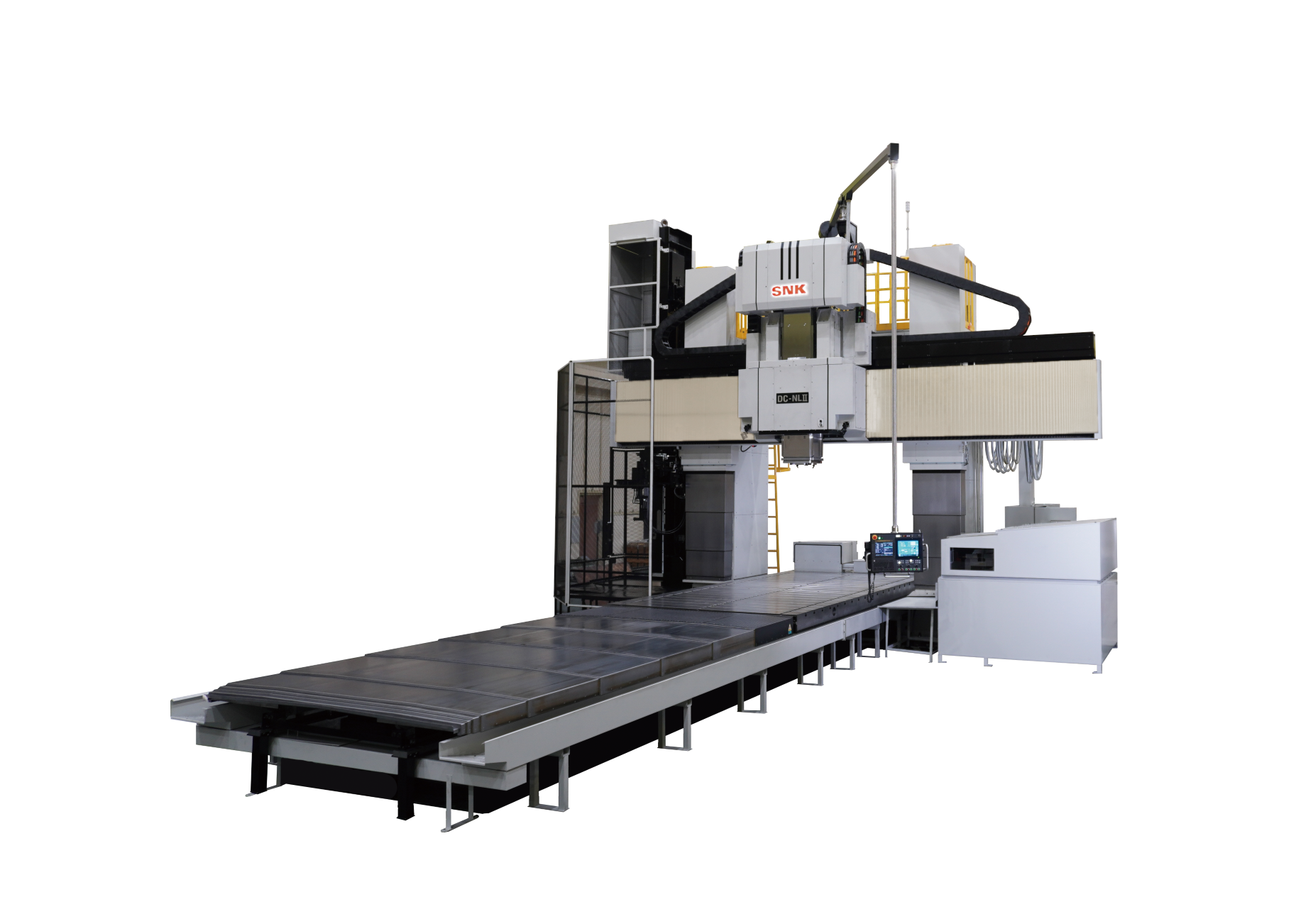

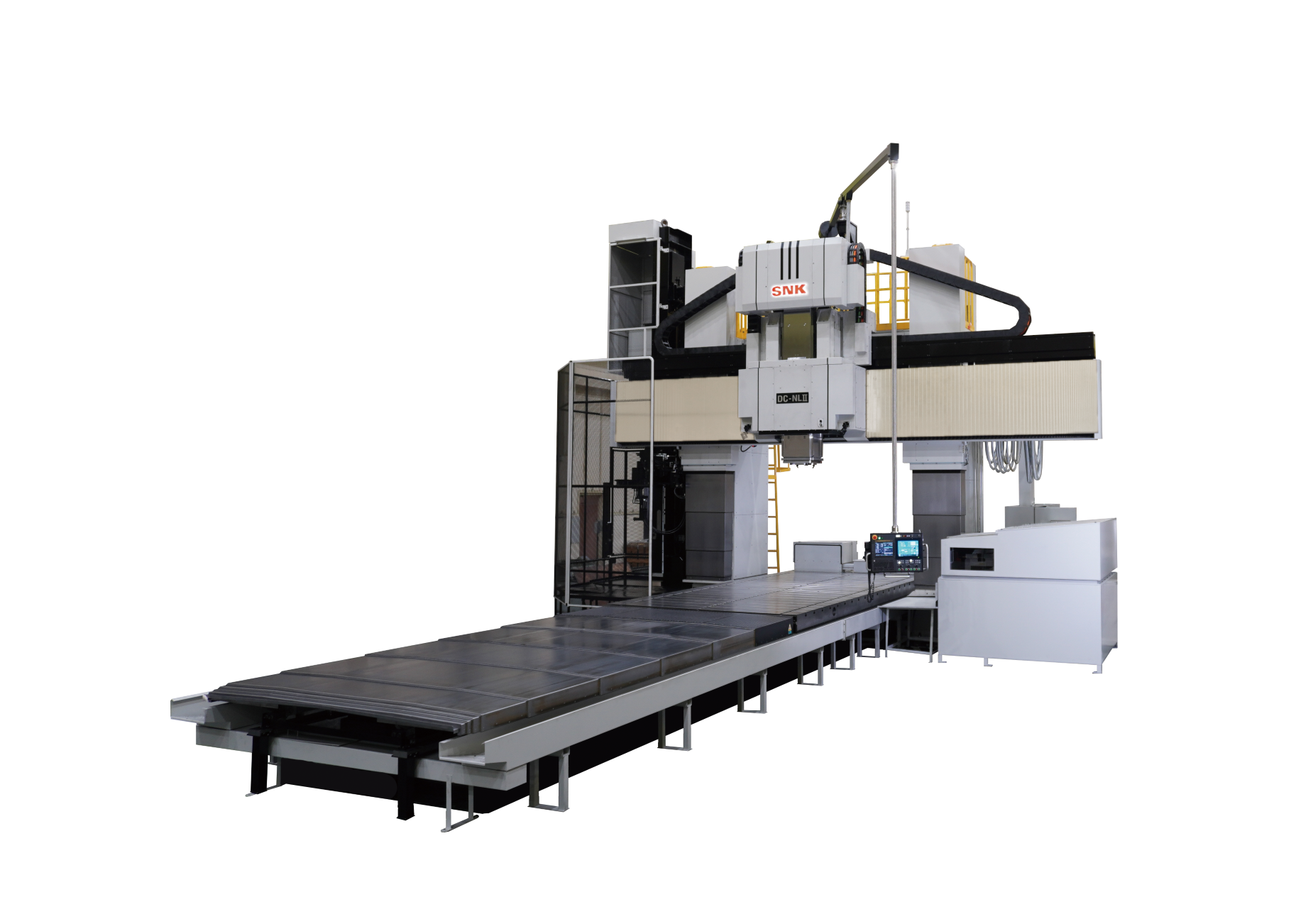

DCⅡHigh speed profile milling machine(Double column type 5-face machining center)

- Automotive

- Aerospace

- General machining

- Shipbuilding

- Heavy electric

- Material

- Semiconductor

- Specialized machines

Electricity consumption reduced by approx. 30%! Masterpiece die & mold processing machine pioneering the carbon-neutral era

DC goes beyond expectations in face quality, shape accuracy and machining speed. When combining the engineering behind the mechanical structure that preserves quality even when accelerating and decelerating at high rates, with the excellent control technology that allows for design reproducibility and the software that maintains the product’s quality even when machining for a long period of time, the result is a machining center that creates dies and on a different level. The DCII series has been developed based on the concept of energy saving and eco-friendly. And in addition to the performance improvements, safety and maintainability have also been improved, offering customers a machine that can be used for a long time.

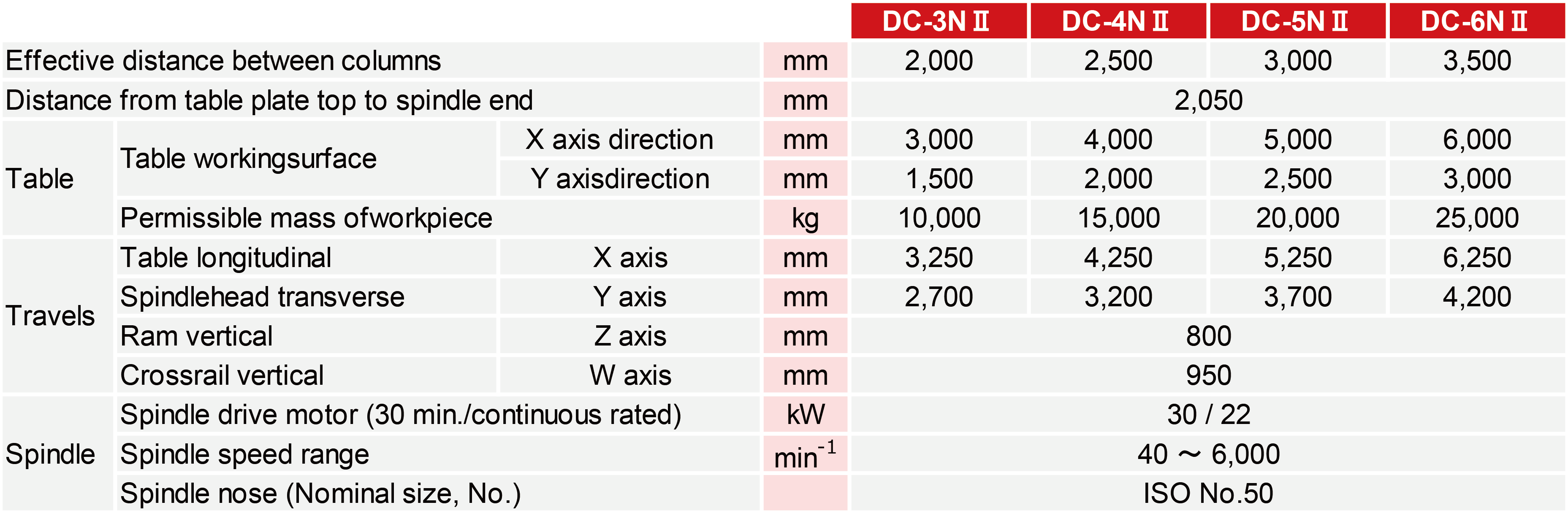

Main specifications

Features

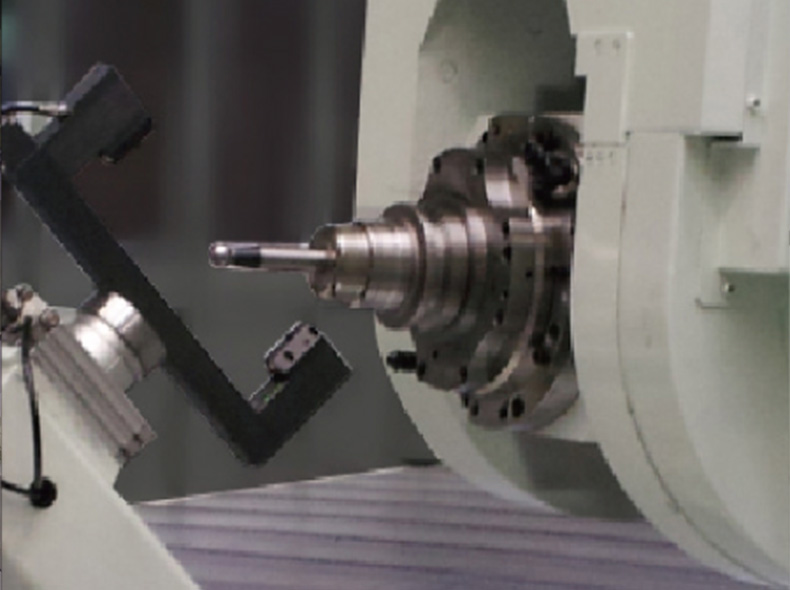

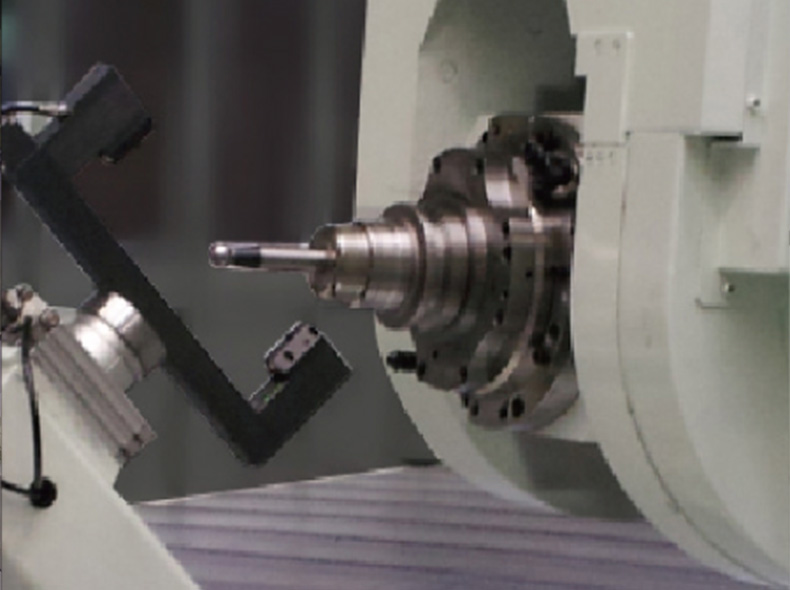

1Faster feedrate of each axis

・Speed increased by strengthening the feed drive/sliding method of the axes

・Twin servo drive on Z / W-axis for high-precision mold processing

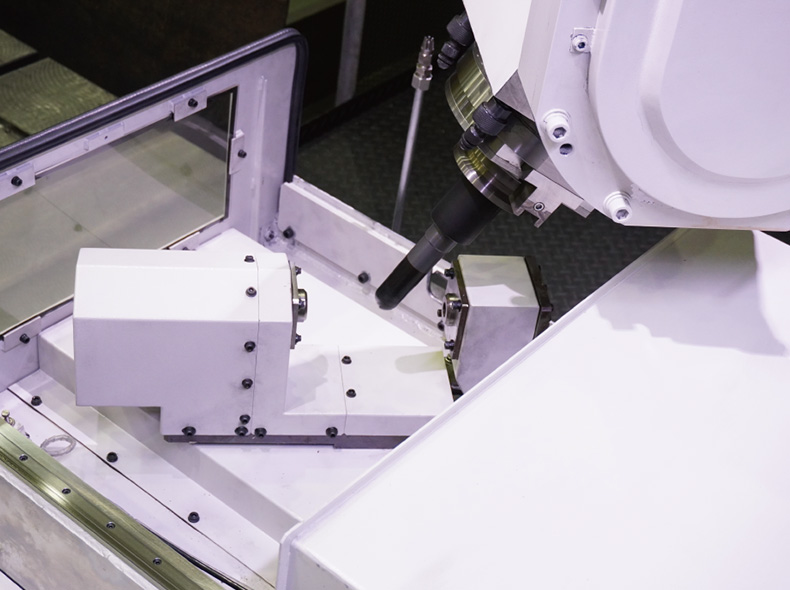

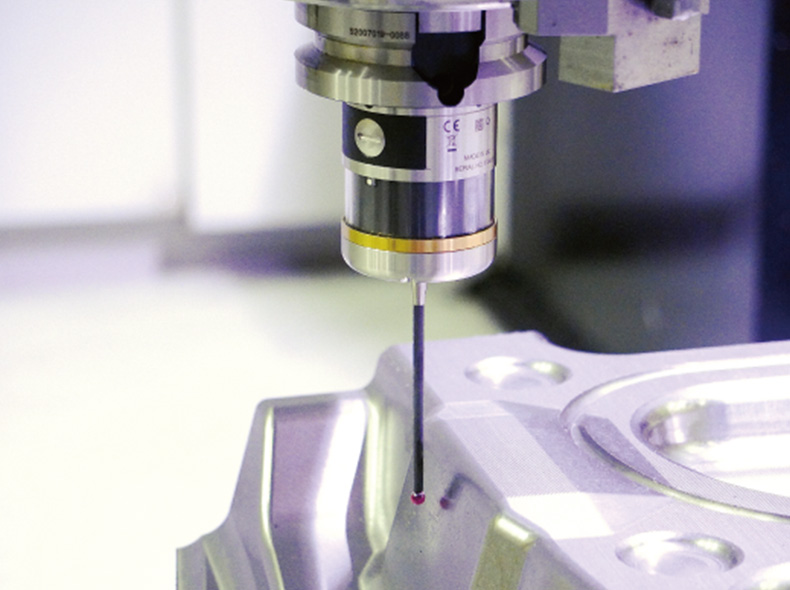

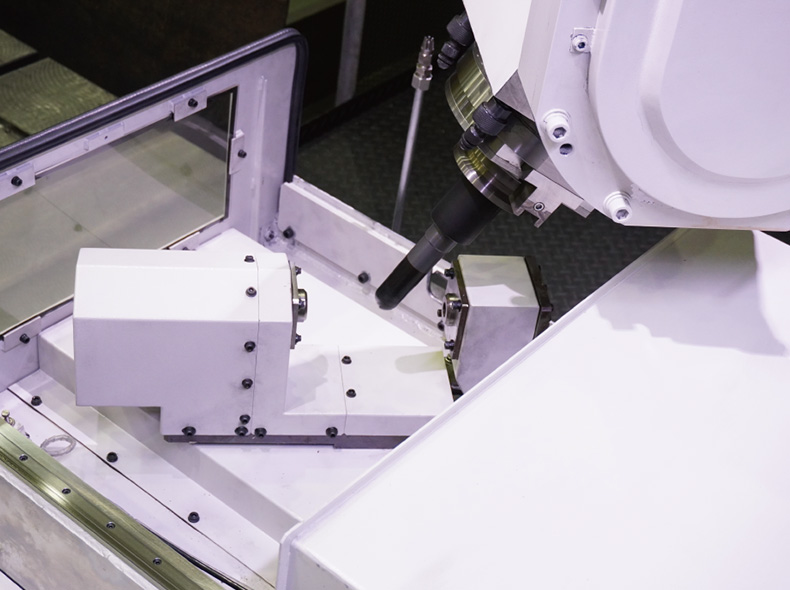

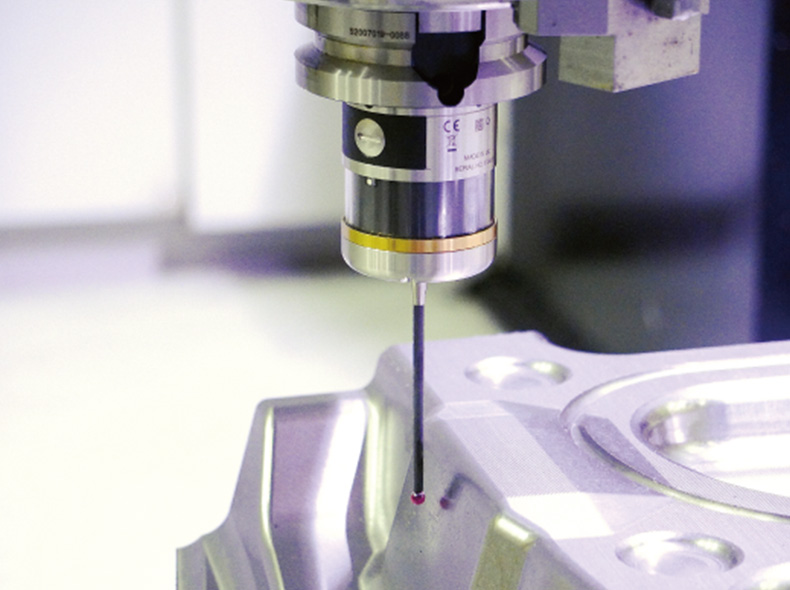

2High-precision functions for gapless machining

・Environmental thermal displacement comensation function

(TDC: Thermo Dynamic Control)

・TR (Thermal Resistance) system

・Camera-type tool measurement device

3Significant reduction in power consumption

・Adopted compact hydraulic unit by eliminating the balance cylinder of the Z / W-axis.

・Inverter control of the hydraulic pump motor reduced approx. 30% of power consumption compared to the previous model.

Movie

Related products

RB-MⅢ

Continuously evolving High-performance Double Column Type 5-face Machining Center

- Effective distance between columns (mm)

- 2,100~3,600

- Table working surface (mm)

- 3,000×1,500~6,000×3,000

- Spindle speed range (min-1)

- 40~6,000

(Maximum 10,000)

RB-FⅡ

A highly rigid continuous 5-axis machining center than can perform powerful 5-axis machining.

- Effective distance between columns (mm)

- 2,100~4,100

- Table working surface (mm)

- 3,000×1,500~6,000~3,500

- Spindle speed range (min-1)

- 40~6,000

(Maximun 30,000)